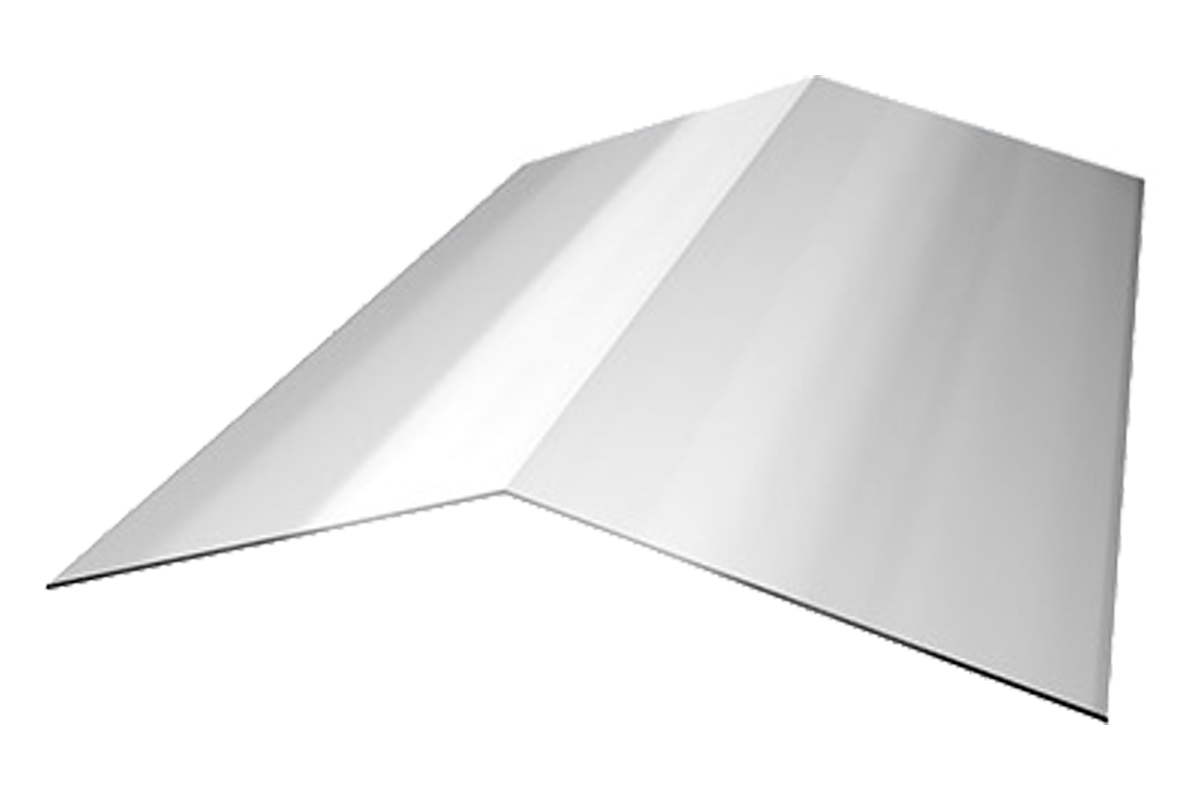

Metal deck construction is a popular choice for creating durable and versatile structures. One essential element in this type of construction is the ridge plate, a crucial component that ensures stability and strength in the roofing system. In this guide, we’ll explore the significance of ridge plates and provide a comprehensive overview of how to use them effectively in conjunction with metal decks.

A ridge plate is a structural element designed to connect and support the two sides of a sloped metal roof at its peak or ridge. It plays a vital role in distributing loads evenly across the metal deck, preventing sagging, and ensuring the overall stability of the structure. Ridge plates are typically made of steel, offering high tensile strength and corrosion resistance to withstand various environmental conditions.

Installation Steps:

- Assessment and Planning:

Before you begin the installation process, thoroughly assess the structural requirements of the building and the specific characteristics of the metal deck. Consider factors such as the roof pitch, load-bearing capacity, and local building codes. - Material Selection:

Choose a high-quality ridge plate that complements the metal deck material. Ensure that the ridge plate is corrosion-resistant, weatherproof, and meets industry standards for strength and durability. - Preparation of Metal Deck:

Clean the metal deck surface to remove any dirt, debris, or rust. Ensure that the deck is free of sharp edges or protruding elements that may interfere with the installation of the ridge plate. - Positioning the Ridge Plate:

Place the ridge plate along the peak of the metal deck, ensuring that it aligns with the centerline of the structure. Use chalk lines or other marking tools to guide the placement of the ridge plate accurately. - Fastening the Ridge Plate:

Secure the ridge plate to the metal deck using appropriate fasteners, such as screws or bolts. Follow the manufacturer’s recommendations for spacing and quantity of fasteners to ensure a strong and secure connection. - Weatherproofing:

Apply weatherproofing measures around the ridge plate to prevent water infiltration. Seal gaps and joints with appropriate sealants to ensure a watertight seal, protecting the underlying structure from potential water damage. - Inspection and Quality Check:

Conduct a thorough inspection of the installed ridge plate to ensure that it meets all structural and safety requirements. Check for proper alignment, secure fastening, and adherence to building codes and regulations.

Incorporating a ridge plate into your metal deck construction is a critical step in ensuring the longevity and structural integrity of the building. By following these installation steps and paying attention to detail, you can master the art of using ridge plates effectively, contributing to a robust and reliable metal deck roofing system.

For more information on high-quality corrugated steel deck products and accessories, call us at 262-857-6400 or get a quote online.