Understanding Metal Decking

Selecting the appropriate metal decking is a critical decision in commercial and industrial construction, directly impacting structural integrity, cost efficiency, and project longevity. This comprehensive guide delves into the nuances of metal decking selection, providing industry professionals with the insights necessary to make informed choices.

Metal decking serves as a structural component in building construction, providing support for roofing systems and forming the base for concrete floors. Its applications range from acting as a permanent formwork framework to serving as reinforcement in composite slab construction. The selection of metal decking influences load distribution, diaphragm action, and overall building performance.

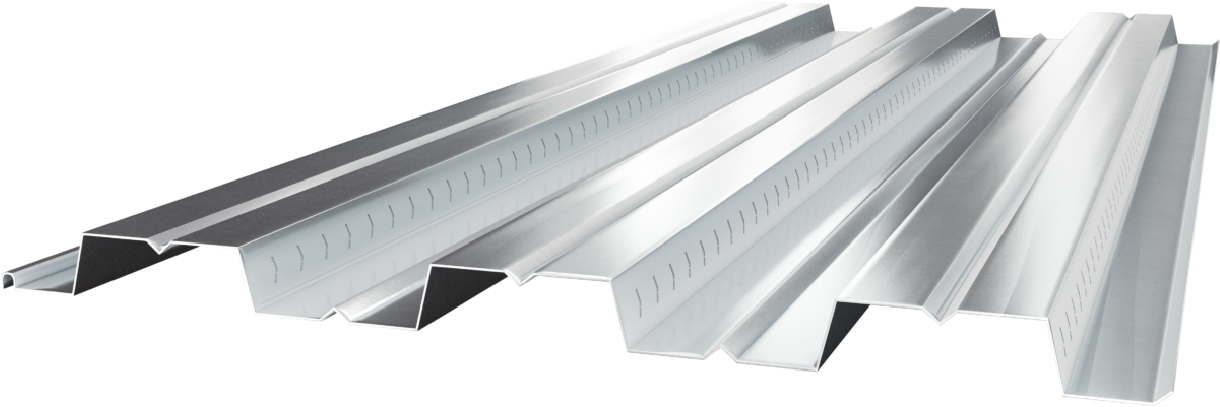

Floor Decking

- Composite Metal Decking:

Designed to bond with concrete slabs, composite decking enhances the slab’s load-bearing capacity. Shear connectors or embossments on the decking surface facilitate this composite action, resulting in a unified structural element. - Form Decking:

Utilized as a permanent framework for concrete slabs, form decking supports the wet concrete until it cures. It does not contribute to the slab’s structural strength post-curing and is selected primarily for its formwork capabilities. - Cellular Decking:

Featuring a flat steel sheet with stiffening ribs welded to a corrugated deck section, cellular decking creates enclosed spaces, allowing for the integration of electrical and mechanical services. This design can also offer enhanced acoustic properties, making it suitable for environments where noise reduction is essential.

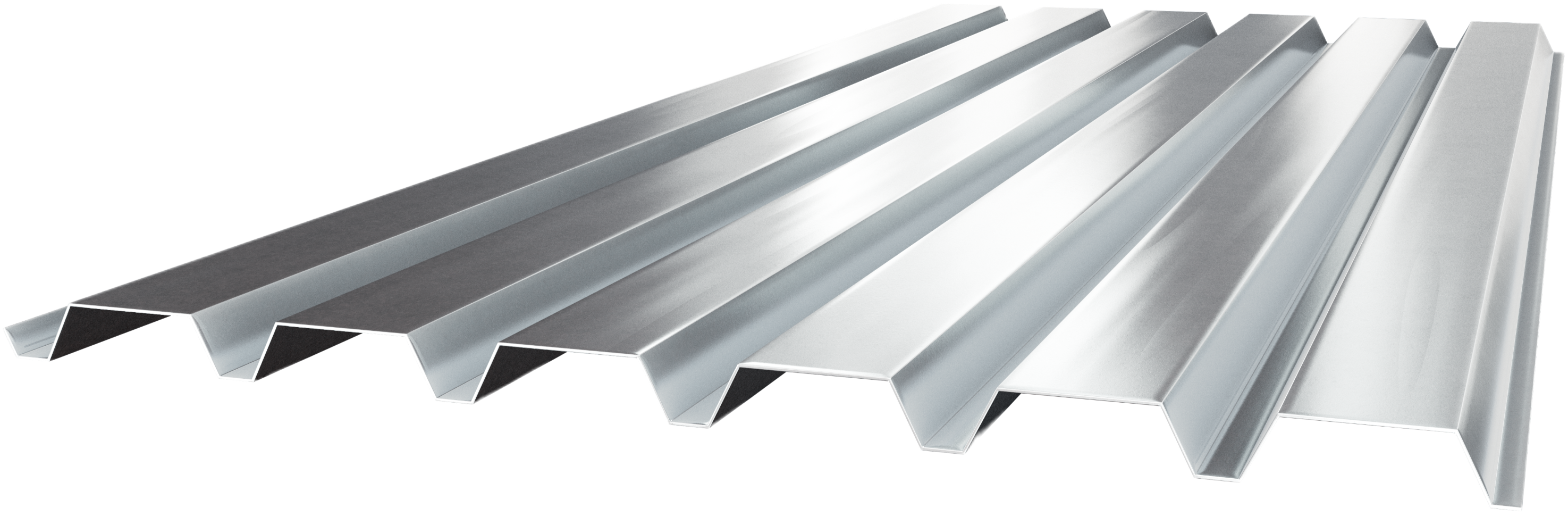

Roof Decking

- Non-Composite Roof Deck:

Serving as the structural substrate for roofing systems, non-composite roof decking provides support for various roofing materials. Common profiles include Type B, Type F, and Type N decks, each offering distinct load and span capabilities. - Acoustic Roof Decking:

Incorporating perforated elements, acoustic roof decking is designed to attenuate sound transmission, making it ideal for facilities with stringent acoustic requirements. - Specialty Roof Decks:

Options such as vented or cellular roof decks cater to specific project needs, including ventilation and enhanced load distribution.

Understanding Materials and Coatings

The performance and durability of metal decking are significantly influenced by the materials and coatings employed.

- Deck Strength:

Deck strength to be provided as specified. All supplied deck has a yield strength of 40ksi or greater. - Galvanized Finishes:

Galvanization involves applying a protective zinc coating to steel to prevent corrosion. Coating designations such as G-60 and G-90 indicate the amount of zinc applied, with G-90 offering superior corrosion resistance. All steel for galvanized metal deck is to conform with the requirements of ASTM A653. - Paint Coatings:

In addition to galvanized finishes, many projects—especially those involving B-Roof decking—utilize painted coatings on cold-rolled steel. All steel for painted metal deck is to conform with the requirements of ASTM A1008. - Specialty Coatings:

In environments with specific challenges, such as high humidity or chemical exposure, specialty coatings provide additional protection, extending the decking’s service life.

Factors to Consider When Choosing Metal Decking

Installation Best Practices

The performance and durability of metal decking are significantly influenced by the materials and coatings employed.

- Deck Strength:

Deck strength to be provided as specified. All supplied deck has a yield strength of 40ksi or greater. - Galvanized Finishes:

Galvanization involves applying a protective zinc coating to steel to prevent corrosion. Coating designations such as G-60 and G-90 indicate the amount of zinc applied, with G-90 offering superior corrosion resistance. All steel for galvanized metal deck is to conform with the requirements of ASTM A653. - Paint Coatings:

In addition to galvanized finishes, many projects—especially those involving B-Roof decking—utilize painted coatings on cold-rolled steel. All steel for painted metal deck is to conform with the requirements of ASTM A1008. - Specialty Coatings:

In environments with specific challenges, such as high humidity or chemical exposure, specialty coatings provide additional protection, extending the decking’s service life.

Trends and Innovations in Metal Decking

The metal decking industry continues to evolve, with emerging trends enhancing performance and sustainability.

- Eco-Friendly Options:

The development of decking materials with recycled content and environmentally friendly coatings supports sustainable construction practices. - Advanced Coatings:

Innovations in coating technologies offer improved corrosion resistance and durability, even in challenging environments. - Integration with Smart Systems:

Modern decking solutions are increasingly compatible with smart building systems, facilitating integrated structural health monitoring.

Partnering with the Right Supplier

In commercial and industrial construction, the success of your project is often determined by the reliability and expertise of your suppliers. Partnering with a supplier who understands the nuances of metal decking and offers quality products can save time, reduce costs, and mitigate risks.

- Reputation and Experience:

Look for suppliers with a proven track record in providing metal decking for similar projects. Check reviews, case studies, and client testimonials to gauge their reliability. - Product Range and Customization:

A supplier with an extensive inventory, including specialized options like acoustical or cellular decking, ensures you can source materials tailored to your project requirements. - Technical Support and Guidance:

Reliable suppliers offer more than just materials. They provide technical support, including load/span tables, installation guides, and expert consultations to help you select the right products. - Certifications and Compliance:

Ensure that your supplier adheres to industry standards such as ASTM, SDI, or ISO certifications, guaranteeing the materials meet rigorous quality and safety benchmarks. - Logistics and Delivery:

Timely delivery is crucial for maintaining construction schedules. Partner with a supplier known for efficient logistics and dependable timelines.

Conclusion

Metal decking is far more than a structural component—it is the backbone of modern commercial and industrial construction. Choosing the right metal decking involves understanding your project’s unique needs, from load-bearing requirements to environmental conditions, and balancing these with budgetary considerations. The right choice enhances safety, durability, and overall project performance, while the wrong choice can lead to costly repercussions.

By staying informed about the types of decking, material options, coatings, and installation best practices, industry professionals can ensure the success of their projects. Furthermore, aligning with a knowledgeable and reliable supplier empowers teams to navigate challenges effectively and deliver high-quality results.

Ready to take the next step? If you’re planning your next commercial or industrial construction project and need personalized guidance, our team of Dexperts® is here to help. Contact a Dexpert today by visiting our contact page and let us provide the expert recommendations and support you need to ensure your project stands the test of time—literally and structurally.