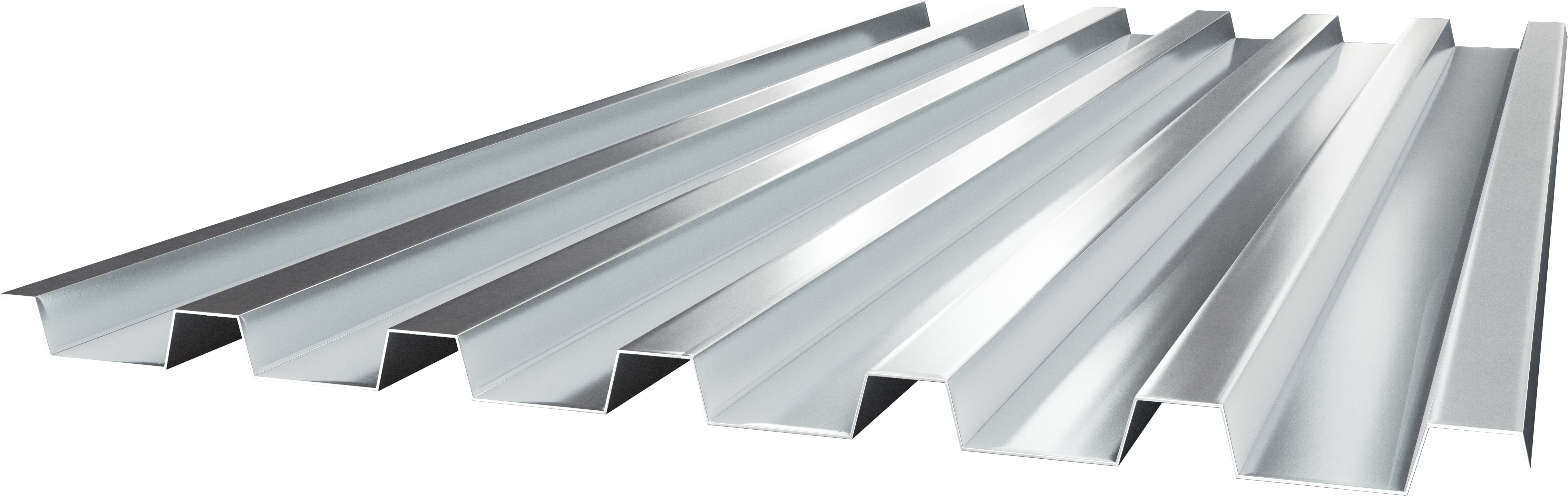

Product Information

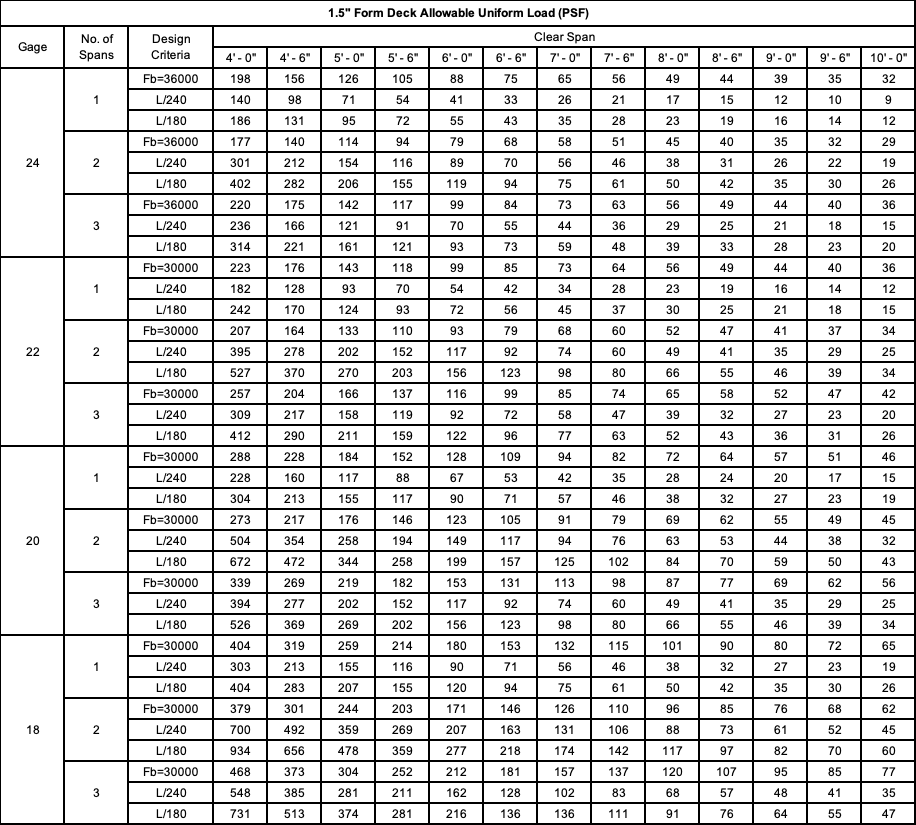

- Cordeck certifies that our Form Deck has been evaluated in accordance with the applicable SDI standards and property values for the Uniform Load Tables, and meets or exceeds SDI requirements.

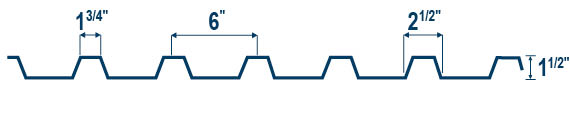

- The rib width limitations shown are taken at the theoretical intersection points of the flange and web projections. Depending on the radius used, the load table could vary from that shown.

All steel to be used in Cordeck Form Deck will be galvanized, prime painted, or a combination of the two.

- Prime Painted

- Form Deck shall receive one coat of standard gray primer paint over cleaned and pretreated steel.

- The primer coat is intended to protect the steel for only a reasonably short period of exposure, in normal atmospheric conditions, and shall be considered an impermanent and provisional coating.

- Field painting of prime painted material is recommended especially where the deck is exposed.

- Galvanized

- All steel shall be coated to conform to ASTM A924 G-60 or G-90 or to Federal Specification QQ-S-775.

- Galvanized finish in G-60 or G-90 coating is desirable in high moisture atmospheric conditions.

- Cordeck shall not be responsible for the cleaning of the underside of steel deck to ensure bond of fireproofing. Adherence of fireproofing material is dependent on many variables. The adhesion ability of fireproofing materials is the responsibility of the fireproofing applicator.

- Accessories

- Cordeck can supply end and side closures, pour stops, deck plates, rubber cell closures, screws and other accessories needed to complete the project.

- All steel deck material is manufactured by Steel Deck Institute members or manufactured in accordance to SDI.

- Cordeck certifies that all material will be in accordance with the SDI Form Deck Manual specifications.

- Cordeck Form Deck conforms to all applicable SDI Form Deck Manual specifications.

- Cordeck steel deck shall be installed by qualified and experienced workers.

- Deck installation drawings shall be submitted to the project architect and engineer for approval prior to the manufacture of materials.

- Deck shall be placed in accordance with approved erection drawings.

- Deck sheets shall be butted over supports.

- End bearing: install deck ends over supports with a minimum end bearing of 1-1/2” or as indicated on erection drawings.

- Each deck unit shall be placed on supporting steel framework and adjusted to final positions before permanently fastened. Do not use unfastened deck as a working platform or storage area.

- Cutting of openings through the deck and all skew cutting shall be performed in the field. Openings not shown on the erection drawings such as those required for stack, conduits, plumbing, vents, etc., shall be cut, and reinforced if necessary, in accordance with SDI.

- Form deck sheets and accessories shall be attached as soon as possible and all sheets and accessories shall be attached at the end of each working day. Electric arc welding is the best and most economical method for attaching form deck sheets to structural supports. Welder shall follow close to the placement crew.

- All welds are to be made from the top of the deck down through the bottom flange of the ribs. Welds shall penetrate and attach all thicknesses of material to the structural supports.

- Deck panels are to be fastened to all supports at 12” on center maximum with no less than 3/4” diameter arc spot welds. At deck butt joints, both sheets are to be fastened. Deck panels with spans greater than 5 feet shall have side laps and perimeter edges (at perimeter supports) fastened at mid-span or 36” intervals, whichever is smaller.

- Puddle welds shall be at least 5/8” diameter or elongated puddle welds with an equal perimeter. Fillet welds, when used, shall be at least 1” long.

- 1-1/2” deep deck side laps are to be screw attached or welded. 2” and 3” deep deck side laps are to be button punched, welded, or Gator Crimp (GTR).

- End closures of the deck, if required, are to be fastened by tack welding or sheet metal screws at 36” centers maximum. Side closures of the deck, if required, are to be fastened by 1” fillet welds at 12” centers maximum.

- Pour stop accessories of the deck, if required, are to be fastened by 1” fillet welds at 12” centers maximum.

Attachment must be determined by the designer as part of the overall building design process. Values given in this document are adequate in most cases.

- Protect steel deck from corrosion, deformation, and other damage during storage, handling, and installation.

- Deck not promptly erected shall be stored off the ground, with one end elevated to provide drainage. Bundles must be protected against condensation with a ventilated waterproof covering. Deck should always be protected from snow and salt.

- Bundles must be stacked so there is no danger of shifting or material damage. Bundles must be checked for tightness, and retightened as necessary.

- Deck bundles on the building frame must always be placed near a main supporting beam, at a column, or a wall. In no situation are the bundles to be placed on unbolted frames or on unattached and unbridged joists. The structural frame must be properly braced to receive the bundles.

Features & Benefits

Prompt lead times are our speciality. All orders are promptly produced and shipped to meet your on-site specifications.

Project management and engineering services are offered by Cordeck’s full, expert, in-house engineering and detailing services to assure optimal planing and design. Our experienced engineers and technicians provide individual customer service and attention to detail from concept to completion.

Bundle Placement plans are provided to ensure correct location of bundles during unloading and hoisting to steel framework.

On-spec, guaranteed quality. Our production staff are true craftsmen, not just interested in getting the job done, but in doing it perfectly.

Knowledgeable, courteous, caring employees throughout our ranks. We’re a “family business”…no “big corporate” attitude here! We genuinely appreciate our customers’ patronage and trust, handling every order, regardless of size, with utmost care and attention.